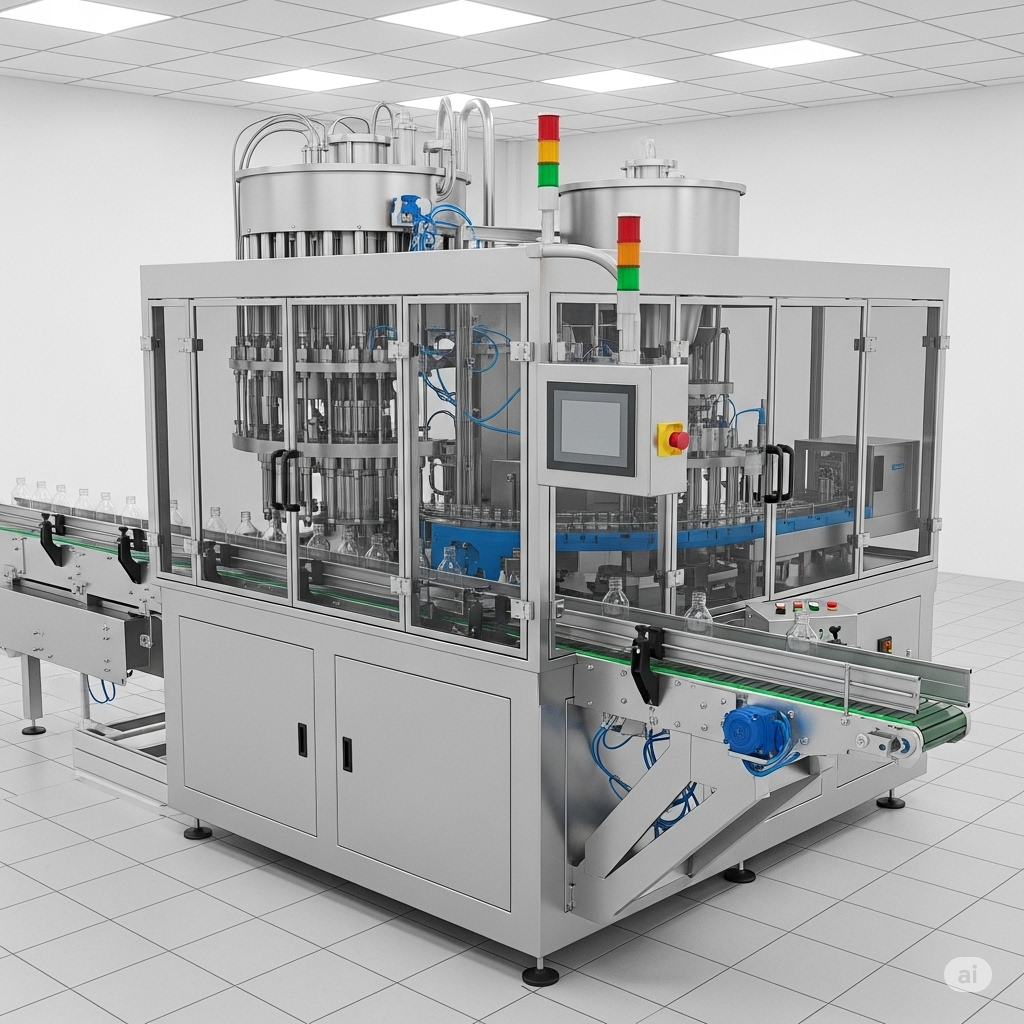

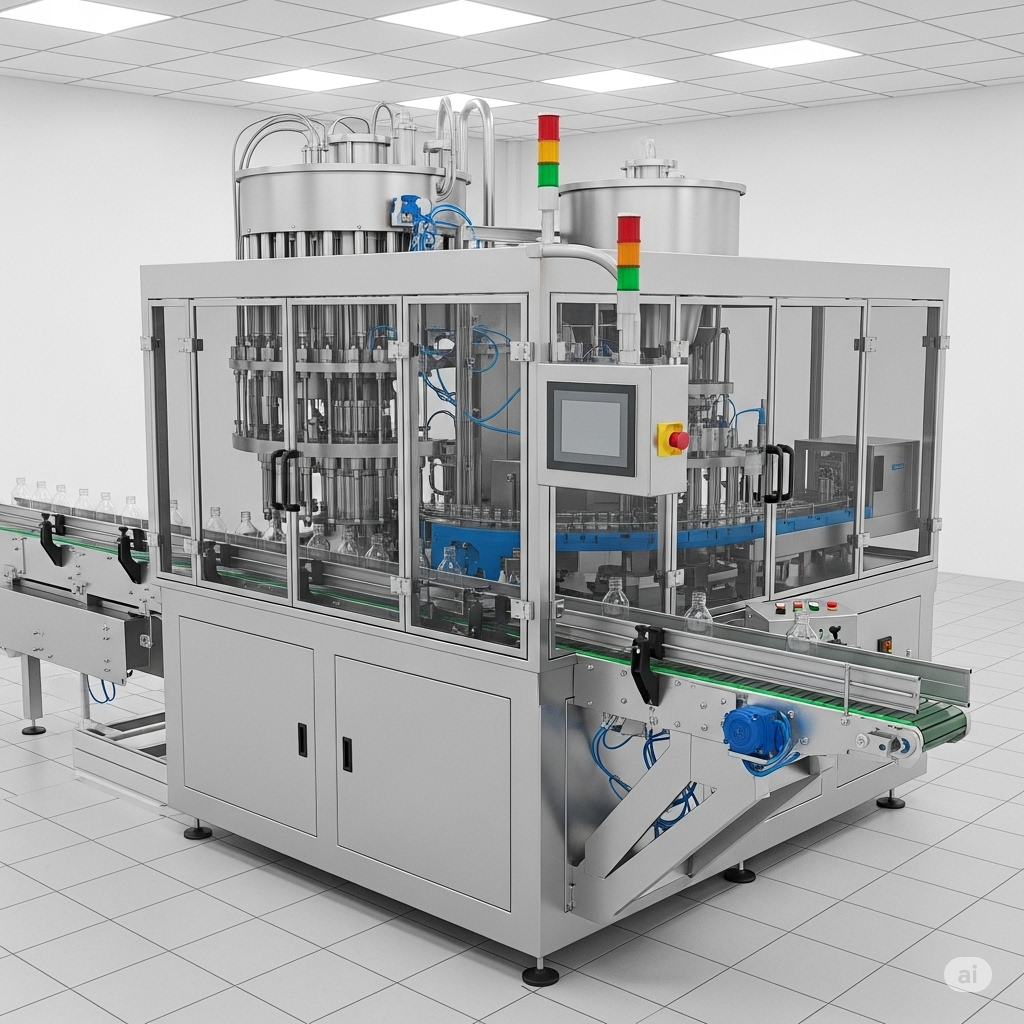

liquid filling machine manufacturersSquare Pharma Machineries

Liquid filling machine manufacturers play a vital role in global industries. As industries grow rapidly today, the need for solutions that improve productivity, accuracy, and quality is increasing day by day. The machines used to fill liquids, in particular, determine the efficiency of a production line. Therefore, choosing the right manufacturer is not a trivial decision — it is a critical decision that directly affects the quality, speed, and cost control of production. Realizing this need, many companies are upgrading their production lines with modern technology. Square Pharma Machineries is a trusted name in this industry. The machines offered by this company facilitate efficient and accurate filling processes in many industries such as pharmaceutical industry, food and beverage manufacturing, and cosmetics.

By choosing the right liquid filling machine manufacturers, companies can increase their production capacity, reduce waste, and deliver a consistent quality end product to the market. At the same time, maintenance costs will decrease, efficiency will increase, and employee confidence will improve. Square Pharma Machineries has been providing world-class machinery with years of experience, combining modern technology with cutting-edge technology. It is not just a machinery manufacturer; it is also a trusted partner for companies looking to streamline their manufacturing processes.

Liquid filling machine manufacturers are companies that design, manufacture and supply machines that accurately and quickly fill liquids into containers such as bottles and vials. These machines are essential in the pharmaceutical, food and beverage, and cosmetic industries. They are used to fill liquid products evenly and accurately in the production line. This improves production efficiency and helps reduce human errors and create a quality product.

Square Pharma Machineries is a leading company in this field. With modern technology, this company is best at providing accurate liquid filling machines without leakage. As a trusted liquid filling machine manufacturer in the global market, it provides suitable solutions according to the needs of industries. liquid filling machine manufacturers :

Types of Liquid Filling Machines

- 1. Volumetric Filling Machines: These machines are used for liquids that have a uniform thickness. The filling volume is correct every time. It is widely used in pharmaceutical and food products.

- 2. Overflow Filling Machines: These are best for evenly filling liquids that flow easily. It is suitable for any type of liquid, from water to juice. Every bottle is the right color and size.

- 3. Piston Filling Machines: These are suitable for products such as thick liquids and creams. In this case, the liquid is filled and measured by a rotating piston under pressure.

Benefits of machines provided by liquid filling machine manufacturers

Playing a very important role in the manufacturing sector, choosing machines provided by liquid filling machine manufacturers brings various benefits to any company. These benefits greatly improve production quality, efficiency, and cost control. The high-quality machines provided by the leading company Square Pharma Machineries are a good example of this.

Increased production efficiency

Automatic liquid filling machines help increase production speed. Thus, more bottles can be filled in several seconds, meeting the increasing needs of the market properly. At the same time, maintaining quality production is the main objective of the production line.

Accuracy and sharpness

The machines provided by Square Pharma Machineries work with precise measurements. By ensuring that the right amount of liquid is filled in each cover, it helps in avoiding wastage of material and ensuring there is no difference in quality.

Improved health and safety

By reducing direct human contact, machines increase the cleanliness of products. This is very important in sectors such as pharmaceuticals and food. This also ensures the safety of workers.

Long-term cost reduction

The initial investment may be a bit high; but the associated cost savings through reduced labor costs, reduced waste, and faster production are all worth it in the long run.

Liquid Filling Machine Manufacturers Step by Step Process

Step 1 – Setup and Calibration

First, it is necessary to calibrate the machine properly according to the type of liquid and the size of the cover. This will ensure accurate and efficient filling levels.

Step 2 – Loading the covers

The covers (bottles, vials) are properly stacked on a conveyor belt and transported to the filling station. This enables orderly and fast production.

Step 3 – Liquid Filling

The machine uses a piston or volumetric method to fill each cover with the required amount of liquid. This ensures that there is no waste of liquid and each cover is filled to an accurate level.

Step 4 – Capping and Sealing

After filling the liquid, the caps are automatically closed or typed (capping). This is important for the safety and long-term preservation of the product.

Step 5 – Packaging and Quality Checking

After being closed, the caps undergo a quality control process and are finally packaged and ready to be sent to the market.

Finally, they are equipped with user-friendly control systems. The machines are very easy to operate with easy-to-understand digital interfaces and a few buttons. This helps the users to handle the machine quickly.

Why choose Square Pharma Machineries as your liquid filling machine manufacturers?

As a trusted and leading liquid filling machine manufacturers in the manufacturing industry, Square Pharma Machineries is a company that specializes in providing innovative solutions, a customer-centric approach and advanced technologies to industries. Here are the key factors to choose Square Pharma Machineries.

Expertise and Experience

With over years of experience, Square Pharma Machineries has been providing unique liquid filling solutions in various sectors such as pharmaceuticals, food and beverages. It has the ability to understand the needs of customers and provide them with the best products.

Customized Solutions

Considering the individual needs of each customer and the special features of the production line, Square Pharma Machineries offers customized liquid filling machine solutions. This enables them to increase production efficiency and control costs.

Pioneering Technology

Square Pharma Machineries is always investing in modern and advanced technology. Through this, their machines have high accuracy, speed and reliability. This provides great benefits to customers.

After-sales Support

As an important aspect, Square Pharma Machineries provides complete support and maintenance to the customers even after the sale. This ensures that the machines are always in top condition and the workers are provided with necessary training.

Why Choose Square Pharma Machineries for Liquid Filling Machines?

Square Pharma Machineries is a leading company in the field of liquid filling machine manufacturers. With its innovative solutions, customer-centric approach and expertise in new technologies, the company offers efficient and best-in-class solutions tailored to the needs of the customer. Here are some of the key factors that make Square Pharma Machineries a good choice.

Expertise and Experience

Square Pharma Machineries is a leading company with many years of experience. It has been providing customized liquid filling solutions to various industries such as pharmaceuticals, food and beverage, by understanding the specific needs of its customers. This experience, combined with the right technology, also improves production efficiency.

Customized Solutions

Square Pharma Machineries creates customized liquid filling machines according to the needs of each customer. This helps in running the production line with greater efficiency. By providing solutions tailored to the specific needs of the customers, it is possible to increase efficiency and quality.

Leading Technology

The company has invested in new technology with the aim of providing the most accurate and fast operation. Therefore, the machines offered by Square Pharma Machineries have high accuracy, speed and reliability. This ensures the quality and speed of the production line.

After-sales Support

Square Pharma Machineries provides assured support to the customers after the sales. Along with the necessary maintenance and training, they ensure that the machines work efficiently. This gives a long-term benefit to the customers.

Tips for Choosing Liquid Filling Machines

There are some important tips and best practices to consider when choosing machines from liquid filling machine manufacturers. This can help you increase your production capacity and quality. Here are some important tips for you:

Understand the properties of your liquid

The viscosity, temperature, and chemical composition of the liquid are very important. These properties play a major role in choosing the right filling machine. Some liquids may be thin, some may be viscous, so you need to choose the right machine for each of these types.

Assess your production volume requirements

Considering your daily or hourly production volume, choose a machine that meets your needs. Choose machines that can produce large volumes without any loss of production capacity. This will help you strike the right balance between quality and speed.

Consider future growth

As your business grows, it is important to choose a machine that has the features to match. If production needs increase, having a machine that can handle that workload will be a long-term benefit.

Make after-sales support a priority

After-sales support and maintenance provided by liquid filling machine manufacturers are essential. Proper maintenance and technical assistance of the machine are essential for it to function smoothly for many years. Some companies offer quality after-sales support, which ensures smooth operations from the beginning of production to the end.

Frequently Asked Questions (FAQs)

- Volumetric Filling Machines: These help in filling the liquid to the exact amount.

- Overflow Filling Machines: These help in filling the correct amount without overfilling.

- Piston Filling Machines: These machines are best for thick liquids like pastes and gels.